Ngokuthuthuka okusheshayo kwe-ibhethri ye-lithiumimboni, izimo zokusetshenziswa kwamabhethri e-lithium ziyaqhubeka nokukhula futhi zibe idivayisi yamandla ebalulekile ezimpilweni zabantu nasemsebenzini.Uma kukhulunywa ngenqubo yokukhiqiza yabakhiqizi bebhethri be-lithium abenziwe ngokwezifiso, inqubo yokukhiqiza ibhethri ye-lithium ngokuyinhloko ihlanganisa izithako, ukugqoka, ukugqoka, ukulungiswa, ukugoqa, ukugoqa, ukugoqa, ukubhaka, umjovo we-liquid, i-welding, njll. Okulandelayo kwethula amaphuzu abalulekile we inqubo yokukhiqiza ibhethri ye-lithium.Izithako ze-electrode ezinhle I-electrode enhle yamabhethri e-lithium yakhiwe ngezinto ezisebenzayo, ama-conductive agents, ama-adhesives, njll. Okokuqala, izinto zokusetshenziswa ziqinisekisiwe futhi zibhakwa.Ngokuvamile, i-ejenti yokuqhuba idinga ukubhakwa ku-≈120℃ amahora angu-8, futhi i-PVDF yokunamathisela idinga ukubhakwa ku-≈80℃ amahora angu-8.Ukuthi izinto ezisebenzayo (i-LFP, i-NCM, njll.) zidinga ukubhaka nokomiswa kuncike esimweni sezinto zokusetshenziswa.Njengamanje, indawo yokusebenzela yebhethri ye-lithium evamile idinga izinga lokushisa ≤40℃ kanye nomswakama ≤25% RH.Ngemva kokuqedwa kokumiswa, ingcina ye-PVDF (i-PVDF solvent, isisombululo se-NMP) idinga ukulungiswa kusenesikhathi.Ikhwalithi yeglue ye-PVDF ibalulekile ekuphikiseni kwangaphakathi nokusebenza kukagesi kwebhethri.Izinto ezithinta ukusetshenziswa kweglue zihlanganisa izinga lokushisa kanye nesivinini esishukumisayo.Ukushisa okuphezulu, ukuphuzi kweglue kuzothinta ukunamathela.Uma isivinini sokuxuba sishesha kakhulu, i-glue ingalimala kalula.Ijubane elithile lokuzungeza lincike kusayizi wediski yokuhlakazwa.Ngokuvamile, isivinini somugqa wediski yokuhlakazeka singu-10-15m/s (kuya ngemishini).Ngalesi sikhathi, ithangi lokuxuba liyadingeka ukuze uvule amanzi ajikelezayo, futhi izinga lokushisa kufanele libe ngu-≤30 ° C.

Engeza i-cathode slurry ngamaqoqo.Ngalesi sikhathi, udinga ukunaka ukuhleleka kokwengeza izinto.Okokuqala engeza izinto ezisebenzayo kanye ne-agent conductive, gxuma kancane, bese ufaka i-glue.Isikhathi sokudla kanye nesilinganiso sokudla kufanele futhi sisetshenziswe ngokuqinile ngokuya ngenqubo yokukhiqiza ibhethri ye-lithium.Okwesibili, isivinini sokuzungezisa kanye nesivinini sokujikeleza kwemishini kufanele ilawulwe ngokuqinile.Ngokuvamile, isivinini somugqa wokuhlakazeka kufanele sibe ngaphezu kuka-17m/s.Lokhu kuncike ekusebenzeni kwedivayisi.Abakhiqizi abahlukene bahluka kakhulu.Futhi lawula i-vacuum kanye nezinga lokushisa lokuxuba.Kulesi sigaba, ubukhulu bezinhlayiyana kanye ne-viscosity ye-slurry kudingeka kubonakale njalo.Usayizi wezinhlayiyana kanye ne-viscosity kuhlobene eduze nokuqukethwe okuqinile, izakhiwo zezinto ezibonakalayo, ukulandelana kokuphakelayo kanye nenqubo yokukhiqiza ibhethri ye-lithium.Ngalesi sikhathi, inqubo evamile idinga izinga lokushisa ≤30℃, umswakama ≤25%RH, kanye ne-vacuum degree ≤-0.085mpa.Dlulisela i-slurry ethangini lokudlulisa noma isitolo sikapende.Ngemuva kokuthi i-slurry idlulisiwe, idinga ukubhekwa.Inhloso ukuhlunga izinhlayiya ezinkulu, ukushona phansi nokususa i-ferromagnetic nezinye izinto.Izinhlayiya ezinkulu zizothinta i-coating futhi zingabangela ukuzikhipha ngokweqile kwebhethri noma ingozi ye-short circuit;impahla ye-ferromagnetic eningi ku-slurry ingase ibangele ukuzikhipha ngokweqile kwebhethri nokunye ukonakala.Izidingo zenqubo zale nqubo yokukhiqiza ibhethri ye-lithium yilezi: izinga lokushisa ≤ 40°C, umswakama ≤ 25% RH, usayizi wemeshi yesikrini ≤ 100 mesh, nosayizi wezinhlayiyana ≤ 15um.

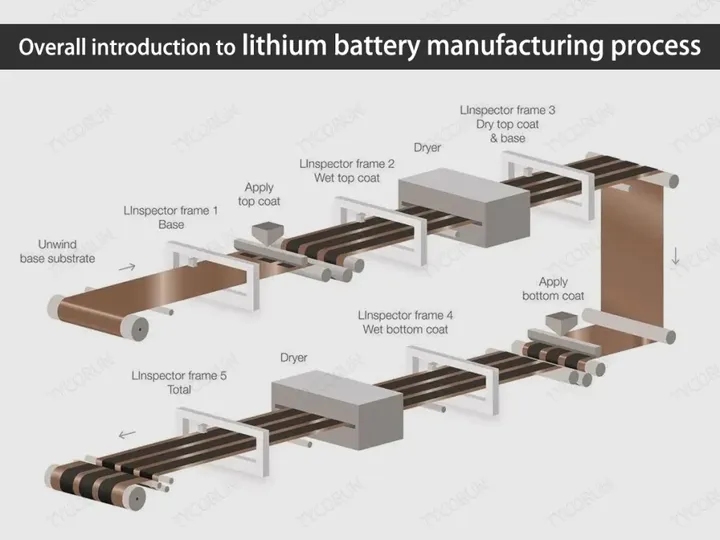

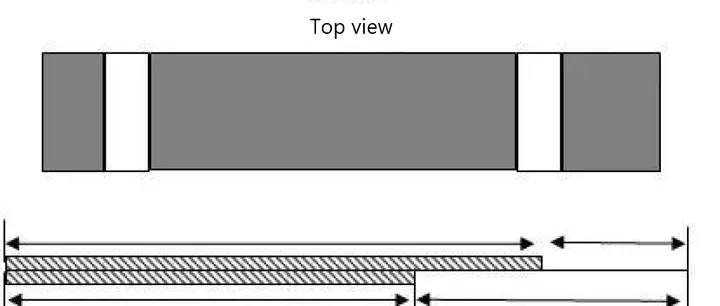

I-electrode engalungileizithako I-electrode engalungile yebhethri ye-lithium yakhiwe ngezinto ezisebenzayo, i-ejenti eqhubayo, i-binder kanye ne-dispersant.Okokuqala, qinisekisa izinto zokusetshenziswa.Uhlelo lwendabuko lwe-anode luyinqubo yokuxuba okusekelwe emanzini (i-solvent ingamanzi angama-deionized), ngakho-ke azikho izidingo ezikhethekile zokomisa zezinto zokusetshenziswa.Inqubo yokukhiqiza ibhethri ye-lithium idinga ukuhanjiswa kwamanzi enziwe nge-deionized ukuthi kube ≤1us/cm.Izidingo zeshabhu: izinga lokushisa ≤40℃, umswakama ≤25%RH.Lungisa iglue.Ngemuva kokuthi kunqunywe izinto zokusetshenziswa, iglue (eyakhiwe yi-CMC namanzi) kufanele ilungiswe kuqala.Kuleli qophelo, uthele i-graphite C kanye ne-agent conductive ku-mixer yokuxuba okomile.Kunconywa ukuthi ungafaki i-vacuum noma uvule amanzi ajikelezayo, ngoba izinhlayiya zikhishwa, zixutshwe futhi zishiswe ngesikhathi sokuxuba okomile.Ijubane lokujikeleza liyijubane eliphansi le-15 ~ 20rpm, umjikelezo wokugaya nokugaya izikhathi ezingu-2-3, futhi isikhathi sokuphumula ≈15min.Thela ingcina ku-mixer bese uqala ukuhlanza (≤-0.09mpa).Cindezela irabha ngesivinini esiphansi se-15 ~ 20rpm izikhathi ezi-2, bese ulungisa isivinini (isivinini esiphansi esingu-35rpm, isivinini esikhulu esingu-1200 ~ 1500rpm), bese ugijima cishe i-15min ~ 60min ngokusho kwenqubo emanzi yomkhiqizi ngamunye.Ekugcineni, uthele i-SBR ku-blender.Ukushukumisa isivinini esiphansi kuyanconywa njengoba i-SBR iyi-polymer ewuchungechunge olude.Uma isivinini sokujikeleza sishesha kakhulu isikhathi eside, iketango lamangqamuzana lizophuka kalula futhi lilahlekelwe umsebenzi.Kunconywa ukugubha ngesivinini esiphansi se-35-40rpm kanye nesivinini esikhulu se-1200-1800rpm imizuzu engu-10-20.I-viscosity yokuhlola (2000~4000 mPa.s), usayizi wezinhlayiyana (35um≤), okuqukethwe okuqinile (40-70%), idigri ye-vacuum kanye ne-screen mesh (≤100 mesh).Amanani enqubo ethile azohluka kuye ngezici ezibonakalayo zezinto ezibonakalayo kanye nenqubo yokuxuba.Indawo yokusebenzela idinga izinga lokushisa ≤30℃ kanye nomswakama ≤25%RH.I-coating cathode coating Inqubo yokukhiqiza ibhethri ye-lithium isho ukukhipha noma ukufafaza i-cathode slurry endaweni engu-AB yomqoqi wamanje we-aluminium, enendawo eyodwa yokuminyana engu-≈20~40 mg/cm2 (uhlobo lwebhethri ye-lithium ye-ternary).Izinga lokushisa lesithando somlilo ngokuvamile lingaphezu kwamafindo angu-4 kuya kwangu-8, futhi izinga lokushisa lokubhaka lesigaba ngasinye lilungiswa phakathi kuka-95°C no-120°C ngokwezidingo zangempela ukuze kugwenywe imifantu ephambanayo kanye nokuconsa kwe-solvent ngesikhathi sokubhaka.Isilinganiso sejubane le-roller yokudlulisa singu-1.1-1.2, futhi indawo yegebe incitshwa ngo-20-30um ukuze kugwenywe ukuminyana okweqile kwendawo yelebula ngenxa yomsila ngesikhathi sokuhamba ngebhayisikili, okungase kuholele emvuleni ye-lithium.Umswakama wokugcoba ≤2000-3000ppm (kuye ngokuthi impahla kanye nenqubo).Izinga lokushisa elihle le-electrode endaweni yokusebenzela lingu-≤30℃ kanti umswakama ngu-≤25%.Umdwebo we-schematic umi kanje: Umdwebo we-schematic we-coating tape

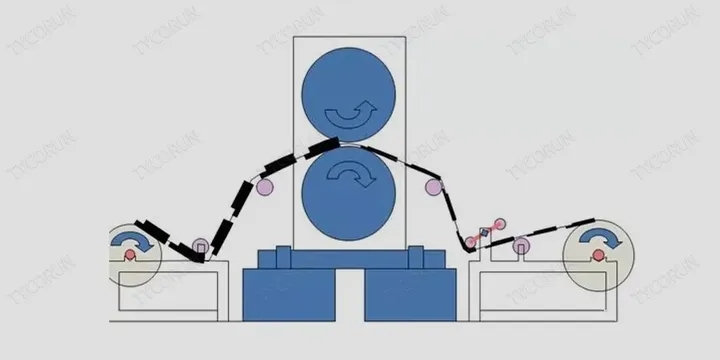

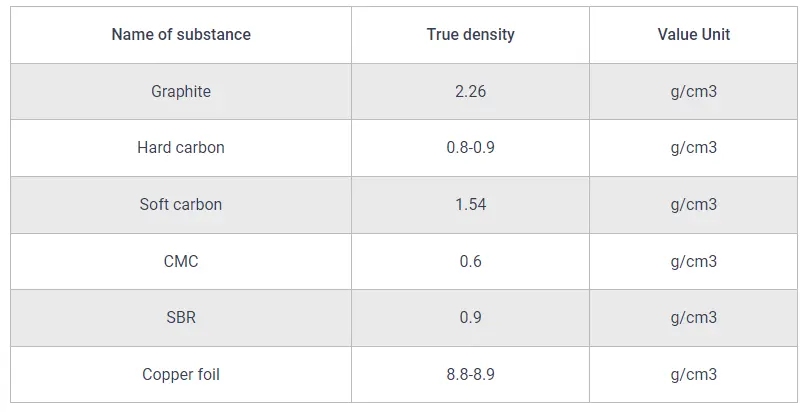

Iukukhiqizwa kwebhethri ye-lithiuminqubo yeukufakwa kwe-electrode negativeisho ukukhipha noma ukufafaza udaka olubi lwe-electrode endaweni engu-AB yomqoqi wamanje wethusi.Ukuminyana kwendawo eyodwa ≈ 10~15 mg/cm2.Izinga lokushisa lesithando somlilo ngokuvamile linezigaba ezingu-4-8 (noma ngaphezulu), futhi izinga lokushisa lokubhaka lesigaba ngasinye lingu-80℃~105℃.Ingalungiswa ngokuvumelana nezidingo zangempela ukuze ugweme ukuqhekeka kokubhaka kanye nokuqhekeka okuphambene.Isilinganiso sejubane le-roller singu-1.2-1.3, igebe lincishisiwe ngo-10-15um, ukugxiliswa kopende kungu-≤3000ppm, izinga lokushisa elingalungile le-electrode endaweni yokusebenzela lingu-≤30℃, kanti umswakama ≤25%.Ngemuva kokuthi ukugqoka okuhle kwepuleti elihle lomile, isigubhu sidinga ukuvumelanisa phakathi nesikhathi senqubo.I-roller isetshenziselwa ukuhlanganisa ishidi le-electrode (isisindo sokugqoka ngevolumu ngayinye).Njengamanje, kunezindlela ezimbili zokucindezela i-electrode ezinhle kwinqubo yokukhiqiza ibhethri ye-lithium: ukucindezela okushisayo nokucindezela okubandayo.Uma kuqhathaniswa nokucindezela okubandayo, ukucindezela okushisayo kunokucinana okuphezulu kanye nezinga lokuphindaphinda eliphansi.Nokho, inqubo yokucindezela okubandayo ilula futhi kulula ukuyisebenzisa nokulawula.Imishini eyinhloko ye-roller ukufeza amanani enqubo alandelayo, ukuminyana kokuqina, izinga lokuphindaphinda kanye nokwelula.Ngesikhathi esifanayo, kufanele kuqashelwe ukuthi ama-chips ama-brittle, izigaxa ezinzima, izinto eziwile, imiphetho ye-wavy, njll.Ngalesi sikhathi, izinga lokushisa imvelo workshop: ≤23℃, umswakama: ≤25%.Ukuminyana kwangempela kwezinto ezivamile zamanje:

I-compaction esetshenziswa kakhulu:

Isilinganiso sokuphindaphinda: ukubopha okujwayelekile okungu-2-3 μm

Ubude: Ishidi le-electrode elihle livamise ukuthi ≈1.002

Ngemva kokuba i-electrode roll enhle isiqediwe, isinyathelo esilandelayo siwukuhlukanisa yonke ingxenye ye-electrode ibe yimicu emincane yobubanzi obufanayo (ehambisana nokuphakama kwebhethri).Lapho usika, qaphela ama-burrs wesiqephu se-pole.Kudingeka ukuhlola ngokucophelela izingcezu zezigxobo ze-burrs eziqondisweni ze-X ne-Y ngosizo lwemishini emibili-ntathu.Inqubo yobude be-burr engu-Y≤1/2 H ukujiya kwe-diaphragm.Izinga lokushisa le-ambient yendawo yokusebenzela kufanele libe ngu-≤23℃, futhi indawo yamazolo kufanele ibe ≤-30℃.Inqubo yokukhiqiza amashidi e-electrode engalungile yamashidi e-electrode e-lithium yebhethri engalungile iyafana neyama-electrode aqondile, kodwa ukwakheka kwenqubo kuhlukile.Izinga lokushisa le-ambient yendawo yokusebenzela kufanele libe ngu-≤23℃ futhi umswakama kufanele ube ≤25%.Ukuminyana kweqiniso kwezinto ezivamile ze-electrode negative:

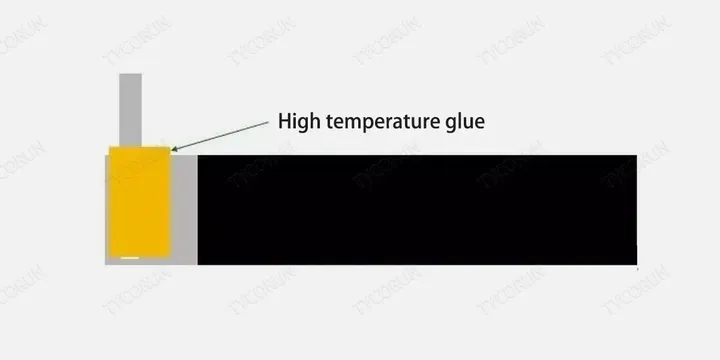

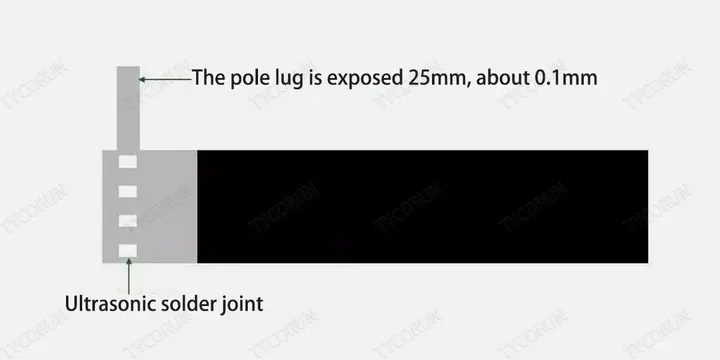

Ukuhlangana kwe-electrode engalungile okuvame ukusetshenziswa: Izinga lokuphinda libuyele: I-rebound evamile 4-8um Elongation: Positive plate ngokuvamile ≈ 1.002 Inqubo yokukhiqiza ye-lithium battery positive electrode stripping iyafana nenqubo yokuhlubula i-electrode positive, futhi kokubili kudinga ukulawula amabharrs ku-X kanye Y izikhombisi-ndlela.Izinga lokushisa le-ambient yendawo yokusebenzela kufanele libe ngu-≤23℃, futhi indawo yamazolo kufanele ibe ≤-30℃.Ngemuva kokuthi ipuleti elihle selilungele ukukhunyulwa, ipuleti elihle lidinga ukumiswa (120 ° C), bese ishidi le-aluminium lishiselwa futhi lihlanganiswe.Phakathi nale nqubo, ubude bethebhu nobubanzi bokubumba kufanele kucatshangelwe.Uma sithatha i- **650 design (efana nebhethri le-18650) njengesibonelo, idizayini enamathebhu aveziwe iwukucabangela ngokuyinhloko ukubambisana okunengqondo kwamathebhu we-cathode ngesikhathi sokushisela i-cap ne-roll groove.Uma ama-pole tabs evezwa isikhathi eside kakhulu, ukujikeleza okufushane kungase kwenzeke kalula phakathi kwamathebhu we-pole kanye negobolondo lensimbi phakathi nenqubo yokugoqa.Uma i-lug imfushane kakhulu, i-cap ayikwazi ukuthengiswa.Njengamanje, kunezinhlobo ezimbili zamakhanda we-welding we-ultrasonic: aqondile kanye ne-point-shaped.Izinqubo zasekhaya ngokuvamile zisebenzisa amakhanda e-welding aqondile ngenxa yokucatshangelwa kwamandla adlulele kanye namandla okushisela.Ngaphezu kwalokho, i-glue ephezulu yokushisa isetshenziselwa ukumboza amathebhu e-solder, ikakhulukazi ukugwema ingozi yezifunda ezimfushane ezibangelwa ama-burrs ensimbi kanye nemfucumfucu yensimbi.Izinga lokushisa elizungezile le-workshop kufanele libe ngu-≤23℃, indawo yamazolo kufanele ibe ≤-30℃, futhi okuqukethwe komswakama we-cathode kufanele kube ≤500-1000ppm.

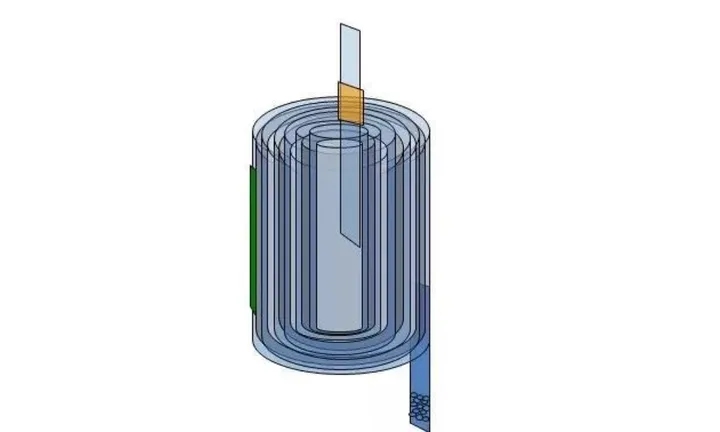

Negative Plate UkulungiselelaIpuleti engalungile idinga ukumiswa (105-110 ° C), bese amashidi e-nickel ahlanganiswe futhi ahlanganiswe.Ubude bethebhu ye-solder nobubanzi bokubumba nakho kudinga ukucatshangelwa.Izinga lokushisa elizungezile le-workshop kufanele libe ngu-≤23℃, indawo yamazolo kufanele ibe ≤-30℃, futhi okuqukethwe komswakama we-electrode engalungile kufanele kube ≤500-1000ppm.Ukuvunguza ukusonga isihlukanisi, ishidi le-electrode elikhangayo neshidi le-electrode elingalungile libe yinkambo yensimbi ngomshini wokusonga.Umgomo ukugoqa i-electrode eqondile nge-electrode engalungile, bese uhlukanisa ama-electrode amahle nebi ngokusebenzisa isihlukanisi.Njengoba i-electrode engeyinhle yohlelo lwendabuko iyi-electrode yokulawula yomklamo webhethri, ukwakheka kwamandla kuphakeme kunalowo we-electrode eqondile, ukuze ngesikhathi sokushaja, i-Li + ye-electrode eqondile ingagcinwa "esikhaleni" se-electrode. i-electrode engalungile.Kudingeka kuqashelwe ngokukhethekile ukungezwani okumazombezombe kanye nokuhlelwa kweziqephu zesigxobo lapho usongwa.Ukuqina okuncane kakhulu okumazombezombe kuzothinta ukumelana kwangaphakathi nezinga lokufakwa kwezindlu.Ukucindezeleka okwedlulele kungaholela engcupheni ye-short circuit noma i-chip.Ukuqondanisa kubhekisela endaweni ehlobene ye-electrode engalungile, i-electrode eqondile, nesihlukanisi.Ububanzi be-electrode engalungile buyi-59.5 mm, i-electrode enhle ingu-58 mm, futhi isihlukanisi singama-61 mm.Zontathu ziqondaniswe ngesikhathi sokudlala ukuze kugwenywe ingozi yamasekhethi amafushane.Ukushuba okusongayo kuvame ukuba phakathi kuka-0.08-0.15Mpa wepali ephozithivu, u-0.08-0.15Mpa we-negative pole, 0.08-0.15Mpa ku-diaphragm engenhla, kanye no-0.08-0.15Mpa ku-diaphragm engezansi.Ukulungiswa okuqondile kuncike ezintweni zokusebenza nenqubo.Izinga lokushisa elizungezile lale workshop ngu-≤23℃, indawo yamazolo ngu-≤-30℃, kanti okuqukethwe komswakama kungu-≤500-1000ppm.

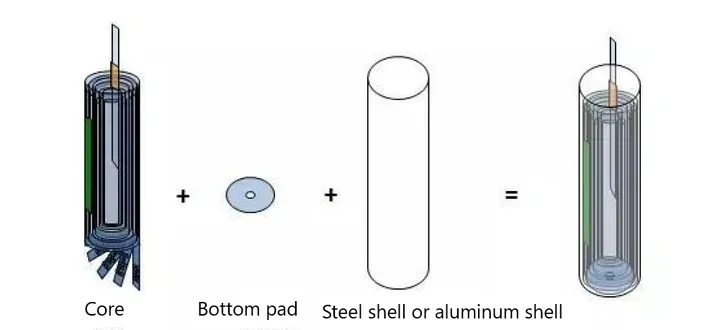

Ngaphambi kokuthi umgogodla webhethri oyikesi ufakwe kukesi, kudingeka ukuhlolwa kwe-Hi-Pot okungu-200~500V (ukuhlola ukuthi ibhethri eline-voltage ephezulu line-circuited yini), futhi ukuhlanza kuyadingeka ukuze ulawule uthuli ngaphambi kokufakwa. icala.Amaphuzu amathathu amakhulu okulawula amabhethri e-lithium umswakama, ama-burrs nothuli.Ngemva kokuba inqubo yangaphambilini isiqediwe, faka i-gasket engezansi ngaphansi komongo webhethri, goba ishidi le-electrode eliphozithivu ukuze indawo engaphezulu ibhekane nembobo yebhethri ejikajikayo, bese ekugcineni uyifake iqonde egobolondweni lensimbi noma igobolondo le-aluminium.Ukuthatha uhlobo lwe-18650 njengesibonelo, ububanzi obungaphandle ≈ 18mm + ukuphakama ≈ 71.5mm.Lapho indawo ephambanayo yomgogodla wesilonda incane kunendawo engaphakathi ephambanayo yekesi lensimbi, izinga lokufakwa kwekesi lensimbi lilinganiselwa ku-97% kuya ku-98.5%.Ngoba inani le-rebound ye-pole piece kanye nezinga lokungena koketshezi ngesikhathi sokujova kamuva kufanele kucatshangelwe.Inqubo efanayo njengoba ukufakwa ngaphansi komhlaba kuhlanganisa ukuhlanganiswa kwe-underlayment ephezulu.Izinga lokushisa le-ambient yendawo yokusebenzela kufanele libe ngu-≤23℃, futhi indawo yamazolo kufanele ibe ≤-40℃.

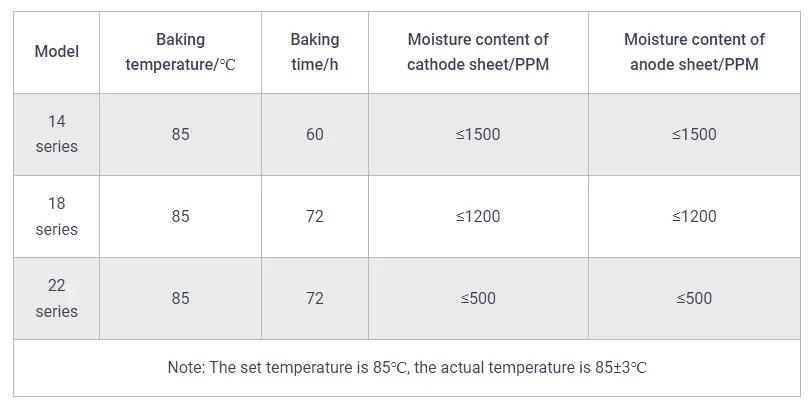

Ukuginqikaifaka iphinikhodi ye-solder (ngokuvamile eyenziwe ngethusi noma ingxubevange) phakathi nendawo ye-solder.Izikhonkwane zokushisela ezivame ukusetshenziswa yi-Φ2.5*1.6mm, futhi amandla okushisela we-electrode engalungile kufanele abe ≥12N ukuze afaneleke.Uma iphansi kakhulu, izobangela kalula i-soldering ebonakalayo kanye nokumelana okukhulu kwangaphakathi.Uma iphezulu kakhulu, kulula ukushisela ungqimba lwe-nickel ebusweni begobolondo lensimbi, okuholela ekuhlanganeni kwe-solder, okuholela ezingozini ezifihlekile njengokugqwala nokuvuza.Ukuqonda okulula kwe-rolling groove ukulungisa umongo webhethri wenxeba ku-casing ngaphandle kokuzamazama.Enqubweni yokukhiqiza yaleli bhethri le-lithium, ukunakwa okukhethekile kufanele kukhokhwe ekufanisweni kwejubane elidlulayo le-extrusion kanye nesivinini sokucindezela i-longitudinal ukugwema ukusika i-casing ngesivinini esiphezulu esiguquguqukayo, futhi ungqimba lwe-nickel lwenotshi luzowa uma isivinini se-longitudinal sishesha kakhulu noma ukuphakama kwenotshi kuzothinteka futhi ukubekwa uphawu kuzothinteka.Kuyadingeka ukuhlola ukuthi amanani enqubo yokujula kwemisele, ukunwetshwa kanye nokuphakama kwemisele ayahambisana yini namazinga (ngokubala okungokoqobo kanye nethiyori).Osayizi be-hob abajwayelekile ngu-1.0, 1.2 no-1.5 mm.Ngemuva kokuthi i-groove egoqayo isiqediwe, wonke umshini udinga ukucocwa futhi ukuze ugweme imfucumfucu yensimbi.Idigri ye-vacuum kufanele ibe ngu-≤-0.065Mpa, futhi isikhathi sokuvala kufanele sibe ngu-1~2s.Izidingo zokushisa ezizungezile zale workshop ngu-≤23℃, kanti indawo yamazolo ingu-≤-40℃.Ukubhaka okuphakathi kwebhethri Ngemva kokuba amashidi ebhethri ayisilinda egoqiwe futhi enziwe grooved, inqubo elandelayo yokukhiqiza ibhethri ye-lithium ibaluleke kakhulu: ukubhaka.Ngesikhathi sokukhiqizwa kwamaseli ebhethri, inani elithile lomswakama liyangeniswa.Uma umswakama ungenakulawulwa phakathi kwebanga elijwayelekile ngesikhathi, ukusebenza nokuphepha kwebhethri kuzothinteka kakhulu.Ngokuvamile, i-oven vacuum ezenzakalelayo isetshenziselwa ukubhaka.Hlela amaseli ukuthi abhakwe kahle, faka i-desiccant kuhhavini, usethe imingcele, futhi uphakamise izinga lokushisa libe ngu-85 ° C (uthatha amabhethri e-lithium iron phosphate njengesibonelo).Okulandelayo yizindinganiso zokubhaka zokucaciswa okuningana okuhlukene kwamaseli ebhethri:

Umjovo OwuketsheziInqubo yokukhiqiza ibhethri ye-lithium ibandakanya ukuhlolwa kokuswakama kwamaseli ebhethri abhakiwe.Kuphela ngemva kokufinyelela izindinganiso zokubhaka zangaphambilini ungakwazi ukuqhubeka nesinyathelo esilandelayo: ukujova i-electrolyte.Ngokushesha faka amabhethri abhakiwe ebhokisini leglavu yevacuum, kala futhi urekhode isisindo, faka inkomishi yomjovo, bese wengeza isisindo esiklanyelwe se-electrolyte enkomishini (ngokuvamile ukuhlolwa kwebhethri elicwiliswe uketshezi kuyenziwa: faka ibhethri enkomishini. phakathi).Faka umgogodla webhethri ku-electrolyte, uyicwilise isikhathi esithile, uvivinye umthamo omkhulu wokumunca uketshezi lwebhethri (ngokuvamile ugcwalise uketshezi ngokwevolumu yokuhlola), ulufake ebhokisini lomshini ukuze uvale (i-vacuum degree ≤ - 0.09Mpa), futhi usheshise ukungena kwe-electrolyte ku-electrode.Ngemva kwemijikelezo eminingana, khipha izingcezu zebhethri futhi uzikale.Bala ukuthi umthamo womjovo uyahlangabezana yini nevelu yomklamo.Uma incane, idinga ukugcwaliswa.Uma kuningi kakhulu, vele ukhiphe okweqile uze uhlangabezane nezidingo zokuklama.Indawo yebhokisi lamagilavu idinga izinga lokushisa elingu-≤23℃ kanye nephuzu lamazolo ≤-45℃.

UkushiselaPhakathi nale nqubo yokukhiqiza ibhethri ye-lithium, ikhava yebhethri kufanele ifakwe ebhokisini legilavu kusengaphambili, futhi isembozo sebhethri kufanele simiswe ekubunjweni okuphansi komshini wokushisela omkhulu ngesandla esisodwa, futhi umgogodla webhethri kufanele ubanjwe ngesinye. isandla.Qondanisa ilugi ephozithivu yeseli yebhethri nelugi yetheminali yekhava.Ngemva kokuqinisekisa ukuthi i-positive lug ihambisana ne-cap terminal lug, gibela umshini wokushisela we-ultrasonic.Bese unyathela unyawo lomshini wokushisela.Ngemva kwalokho, iyunithi yebhethri kufanele ihlolwe ngokugcwele ukuze kubhekwe umphumela wokushisela wamathebhu e-solder.

Bheka ukuthi amathebhu e-solder aqondile yini.

Donsa kancane kuthebhu ye-solder ukuze ubone ukuthi ayikhululekile yini.

Amabhethri ikhava yebhethri yawo ingashiselwe ngokuqinile adinga ukushiselwa kabusha.

Isikhathi sokuthumela: May-27-2024